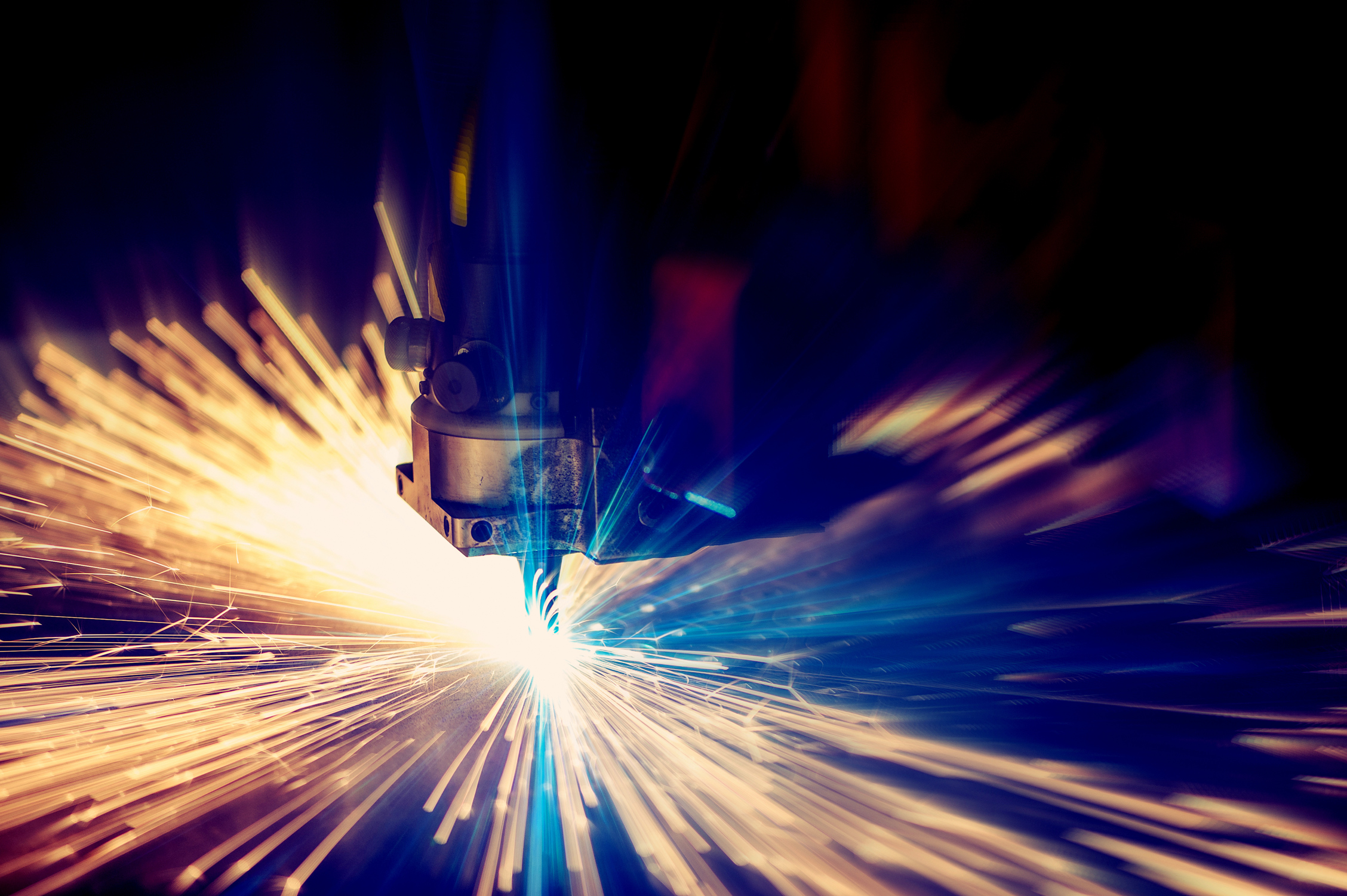

CNC Laser Cutting + Punching

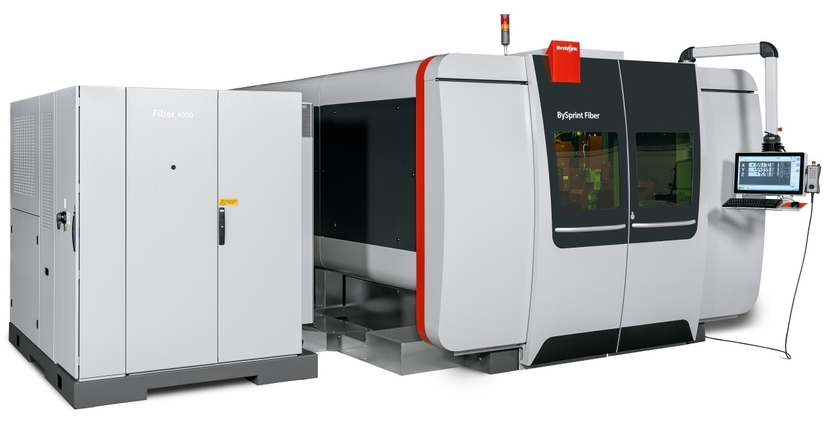

Ultratech now features two 3kw Bystronic fiber lasers on our shop floor. These machines allow us to cut both ferrous and non-ferrous materials at rapid speeds with exceptional precision and minimal downtime. Both machines are equipped with shuttle tables to provide automated material loading of sheets up to 5′ x 10′. A fiber laser is a cost-effective method to produce prototypes and parts with complex geometries without purchasing tooling.

Our punching department consists of two 30-ton king turret punch presses. Both machines have scratch-free brush tables and can process up to 4′ x 8′ sheets of material. For long running projects one of the turrets is equipped with an automated loader/unloader for lights-out production capability. Similar to the combo machine, the turret presses complete part marking, machining, and forming operations such as taps, countersinks, embosses, bridge lances, and extrusions in one setup. For medium to high volume manufacturing the turret press is a highly cost-effective solution.

The latest addition to our floor is 20-ton punch/2kw fiber laser combo machine. This offers the best of both worlds for thin-gauge sheet metal fabrication. It processes 4′ x 10′ sheets on a scratch-free, brush table, maximizing part yields and minimizing post-processing. The laser provides flexibility and speed, while the turret offers part marking, machining, and forming capability to complete taps, countersinks, embosses, bridge lances, and extrusions in one setup. As a complete package it is a powerful manufacturing tool.

We provide precision sheet metal fabrication and assembly services to a diverse customer base, including OEMs and Contract Manufacturers, located throughout North America, Europe and Asia.

Contact us Today and Let’s discuss your Project!

REQUEST A QUOTE